The perfect low cost and good quality tower solution for start-up sites.

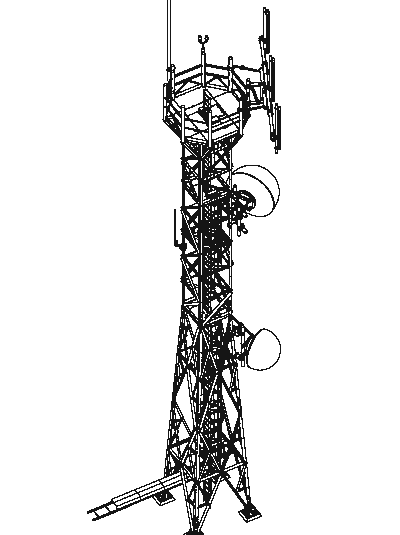

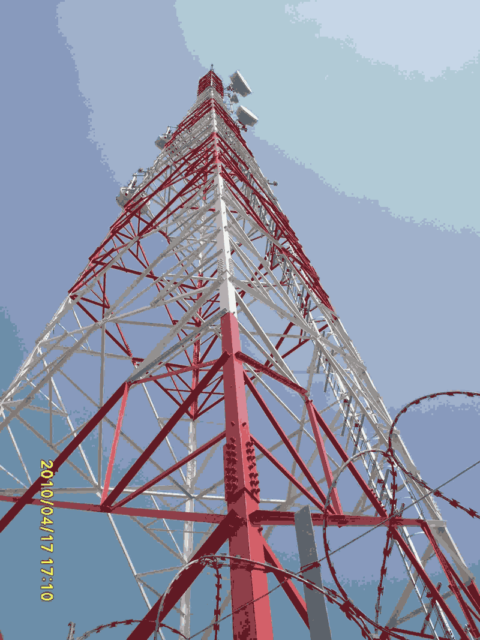

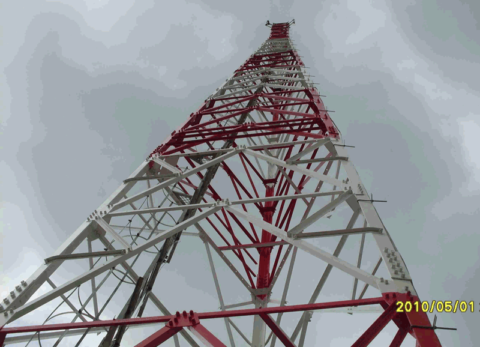

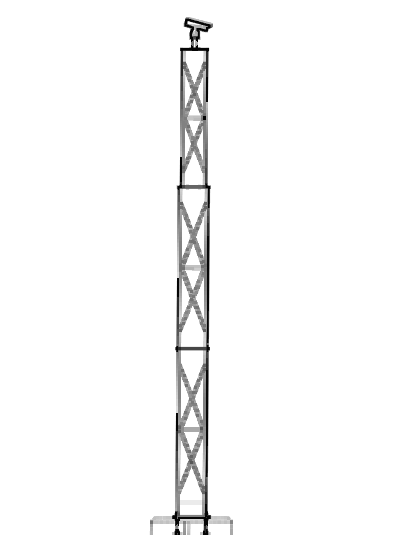

Telecom Lattice Mast Tower

SKY NETWORKS lattice tower provides the perfect low cost and good quality tower solution for start-up sites – Lattice mast tower of Angular legs or Tubular legs, 3 legged or square one.

- Cost-effective design solutions in accordance with latest ANSI/TIA-222 code, specially suitable for start-up sites;

- Designed to meet the RF & MW requirements of telecom operators and vendors, as well as co-location load requirements of several operators;

- Optimized for container loading shipment and easy to erect;

- Excellent support service including professional site supervision and supplementary components;

– – Design

Sky Networks engineers are qualified and experienced structural design engineers. Having developed over 100 designs complying to various industry standards and requirements.

Towers are designed using latest software based programs which takes into account various parameters, such as:

– Wind load conditions;

– Antenna (GSM & MW) loading height & dimensions;

– Feeding cable load conditions;

– Ice load conditions;

– Topography factor;

– Dynamic effect of wind;

– Factor of safety;

– Codes / Standards requirements, and etc.

Design software utilized:

– Risa Tower & Risa3D

– PLS tower

– X-Steel

Design standards mostly utilize EIA/TIA-222-G (Telecommunications industry association) for International approval;

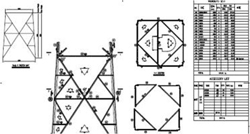

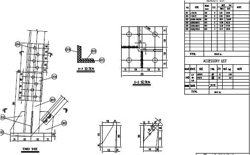

– – Detailing

Generation of structure drawing for workshop drawing generation and site installation purpose.

Generation of Bill of Material (BOM)

Workshop drawing for manufacturing based on structure drawing & BOM.

Software utilizing AutoCAD Ver 2008 or above

Production Capacity: 2000 MT/monthly

Galvanization Capacity: 8000 MT/monthly

– – Prototype Assembly and Inspection

Dedicated independent prototype assembly units

Prototype inspection done by internal QA Team, Third party or customer are also applicable for the Final Approval and mass production.

– – Fabrication

Fabrication Capacity : 2,000 MT/month

Galvanization Capacity : 8,000 MT/month

Main machines & equipments for Lattice Tower Production

-CNC cutting

-CNC Angle punching and stamping

-CNC Plate punching and stamping

-Angle cropping with Stamping

-Hydraulic press machines for angle cutting, hole and number punching machines

-Notch cutting machines

-Angle bending machines

-Radial drilling machines

-Welding machines

– etc…

– – Hot-Dip Galvanization

– – Pack & Delivery

![]() – – DESIGN

– – DESIGN

Structural steel design according to latest international standard (ANSI/TIA-222 code:

– Design wind speed (EIA-222): 125km/h, up to 160km/h

– Constant operational wind on entire height: 100km/h, up to 130km/h

– Top deflection (operational wind speed): default 0.5degree

![]() – – MATERIAL

– – MATERIAL

Comply with the requirements of Chinese Standards, which are equipvalent to ISO standards:

– Main members Q345B/A572, auxiliary Q235B/A36

– Nuts and Bolts GB 3098.1.2 Grade 8.8

![]() – – MANUFACTURE

– – MANUFACTURE

– Welding as per code AWS1.1 and GB50205-2001, GB50017-2003

– Surfaces are treated by hot-dip galvanizing in accordance to Chinese GB13912-2002 and ASTM A123/A123M:

– Paint finish of metallic structure upon requirement in RAL color range.

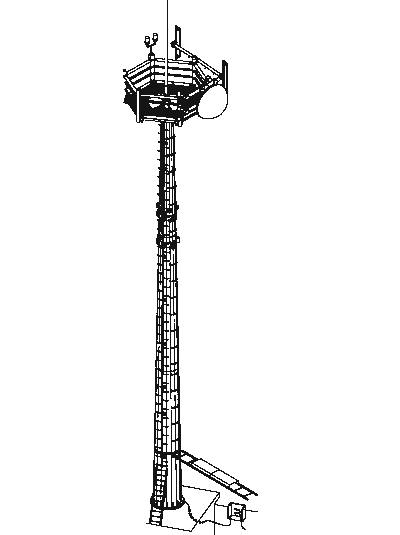

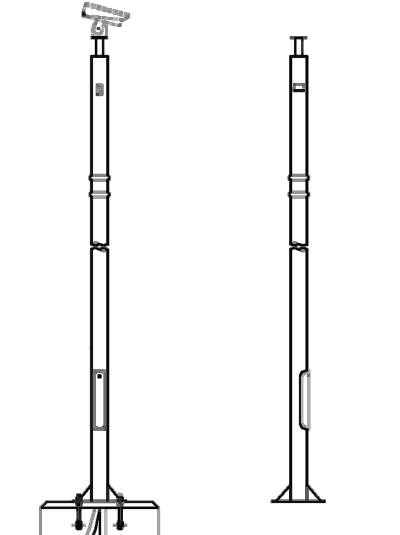

![]() – – SUPPLY

– – SUPPLY

Standard supply provides the minimum configuration required for pole commissioning, excluding radiant systems and mounts.

– Foundation set (Anchoring bolts & setting templates)

– Supporting structure, may divided into shafts/sections considering container length limitation;

– Touch-up paint as option when required.

– Packing list with assembly and maintenance instructions

– Packing & shipment;

* Telecom Lattice Tower is a custom designed product complying with your project specifications. Please contact us with detailed requirements.